Do you know the history of label printing or how it works today? Are you wondering if your business could benefit from label printers? You've come to the right place! Let's take a deep dive into this office equipment to find out everything about label printing.

Label Printers: A History

The very first label printers were, of course, people. Back in the 1800s, we put images on paper and applied adhesive gum to the back. To activate the gum's sticky quality, you'd have to lick it.

The next significant advance in label printing occurred in the 1930s when the first self-adhesive label was invented. From there, technology continued to advance, including the addition of new materials like vinyl. Finally, the 1990s brought digital label printing into the spotlight through accessible office equipment.

Today, you can print labels right in your office--all without having to lick any adhesive gum!

Label Printing with Modern Office Equipment

Now that you know what label printing used to look like, let's find out how it works today.

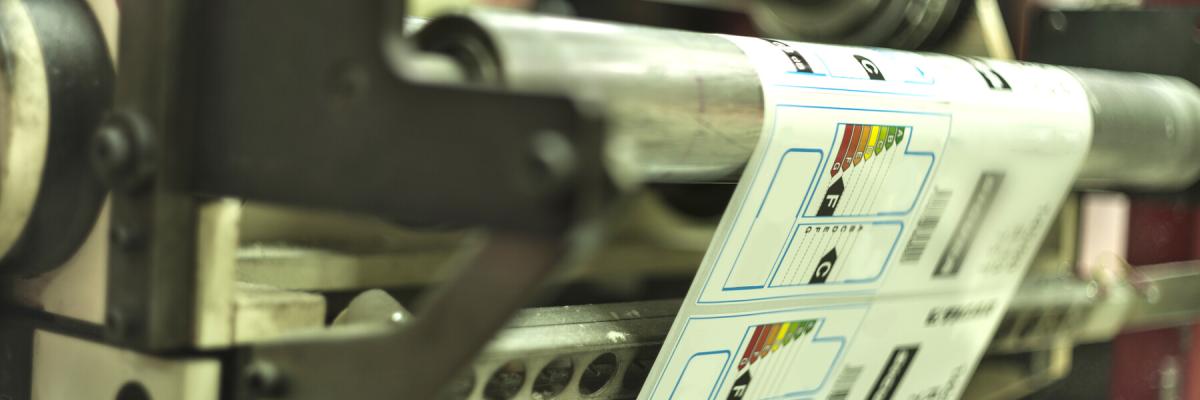

The label printing process comes in two basic forms: direct thermal and thermal transfer:

Direct thermal

You see direct thermal labels every time you get a receipt at the store. The process for creating these labels is simple: A blank label moves under the printhead, heat is applied, and a chemical reaction occurs which causes certain areas to darken. The result is an image that, while useful, isn't scratch-resistant or particularly reliable in high heat.

Thermal transfer

More durable and reliable than their direct thermal cousins, thermal transfer label printers rely on ribbons to get the job done. These ribbons hold ink, which is used with printheads to apply an image directly to your chosen media.

Conclusion

In conclusion, there's plenty to know about label printers and the process overall--but the biggest question is whether you need office equipment that can do all this and more.

If you're ready to print labels at the tap of a button, contact us today to learn more about label printers!